Oil & Gas

Oil & Gas Solutions

Keep your operators, equipment, and environment safe by accessing corrosive or harmful materials using safe, efficient sampling equipment. This regular testing is critical to product quality, maintaining EPA (and other) standards, and maintaining operational efficiency. Learn more about how Sentry's solutions focus on a high level of protection while minimizing impacts to your bottom line.

Low Emission Samplers

Maximize safety to the operator and the environment with Sentry's low-emission samplers.

Learn More

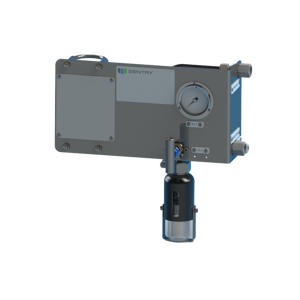

Corrosion Monitoring

Safely treat and protect your pipelines with Sentry's complete portfolio of corrosion protection equipment.

Learn More

ProShield Plant Service

The Sentry ProShield Plant Services team looks upstream, downstream, and everywhere in between to find creative and lasting solutions to your unique process needs.

Learn More

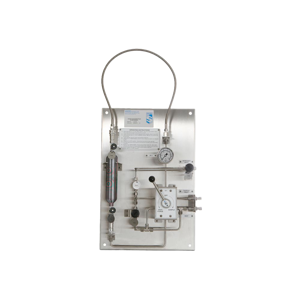

Sample Coolers

Designed to handle a variety of sample temperatures and volumes, Sentry sample coolers ensure your samples are ready for safe, efficient testing.

Learn MoreCommitted to Your Processes

Protecting people and processes is at the core of everything we manufacture. Within oil and gas processes that protection becomes critical. From environmental requirements to operator protection, oil and gas production needs to be under stringent control to reduce costs and maximize safety. It is this challenge that drives our sampling, retrofitting, and custom application solutions.

Sentry customers rely on our commitment to gain accurate grab samples, ensure their processes run smoothly, and manage their risk of corrosion and other contamination. Each of Sentry's equipment and service solution safeguards these concerns throughout their lifecycle by focusing on the way your processes should work.

Looking for More Information?

Learn more about the impacts of preventative maintenance and sampling management with these related resources.

ProShield Oil and Gas Service Brochure

Learn how our ProShield technicians can keep you up and running with their oil and gas capabilities.

Download Now

Corrosion Monitoring & Mitigation eBook

Unchecked corrosion can lead to process failures and at the worst, cause environmental and personnel risks. Learn how to mitigate these concerns with this eBook.

Download Now

What is Representative Sampling?

Operators can produce reliable and accurate analysis results that meet federal requirements through representative sampling. Learn how you can implement this at your plant through our beginner’s guide.

Download the eBook

Manual Sample Equipment Brochure

Find the sampling equipment that is right for your application with our Manual Sampling brochure. Whether you are sampling high temperatures or caustic liquids, Sentry's line of Low-E samplers has you covered.

Download BrochureExtra Protection Made Simple

Avoid harmful process consequences such as corrosion, unreliable analyzers, and inconsistent temperatures by adding an extra layer of protection to your oil and gas applications. From sample coolers to manual samplers, find the products you need to minimize equipment damage, personnel harm, and costly downtime.

Trust the Pros That Know

Critical analytics and chemical processing equipment can become obsolete ahead of plan, resulting in the need for safe, efficient technology updates. From installation to retrofitting and designing custom solutions, Sentry ProShield has you covered.

Sentry's technicians go beyond one-size-fits-all to provide installation, product support, and application engineering to custom design updated solutions for your existing analysis system. Each installation and retrofit starts with a complete review of the system (SysRep) and takes into account a holistic, iterative focus to minimize impacts to your processes and equipment.

By focusing on reliability and brand inclusivity, you are able to get the full range of expertise from our trusted technicians.

Recommended Product Lines

Get started finding the right equipment for your application with these recommended products by Sentry Equipment.

Need More Insight?

Explore our blog, the Shield, for more Oil and Gas information.