Many fuel production plants have converted or are planning to convert traditional refining processes to biodiesel or biofuel production processes to reduce their footprint. However, this conversion may pose many challenges, including ensuring that sampling processes are used to sample these fuels properly and safely.

Hydrocarbon is Facing Increased Legislation and Regulation

The Renewable Fuel Standard (RFS) program is a national policy that requires a particular volume of renewable fuel to replace or reduce the quantity of petroleum-based transportation fuel, heating oil, or jet fuel. The Energy Independence and Security Act of 2007 (EISA) significantly increased the size of the RFS program by boosting long-term production goals to 36 billion gallons of renewable fuel per year.The RFS program includes four categories of renewable fuel:

- Advanced biofuels are produced from types of renewable biomass, such as sugarcane, biobutanol, and naphtha.

- Biomass-based diesel is produced from biomass such as soybean oil, canola oil, waste oil, and animal fats.

- Cellulosic biofuel- produced from cellulose or hemicellulose of corn stover, wood chips, Miscanthus ornamental grasses, or biogas.

- Conventional renewable biofuel- including ethanol from corn starch or other renewable fuels.

Maximize Safety with Representative Sampling

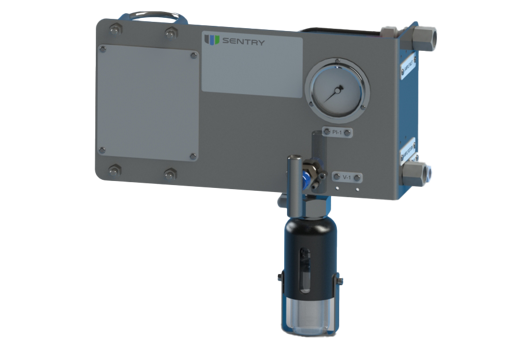

During production, renewable fuels undergo many processes like traditional fuels, making it essential to sample them for quality, safety, and integrity, just as you would in a conventional refinery.Sampling can help production plants meet strict environmental standards, maximize product quality, ensure product integrity, and maintain the safety of personnel and equipment.

The first step in ensuring proper sampling is to sample at suitable locations within the biofuel production process. These can include:

- Renewable feedstock sources- Sample raw materials before production to ensure appropriate ingredients enter the process.

- Intermediate hydrodeoxygenation (HDO) products- Sample products to ensure sufficient removal of oxygen.

- Hydrogen Sulfide- Sample for hydrogen sulfide (H2S) to ensure elimination of corrosive contaminants.

- Sour water—Sample to ensure sufficient removal of H2S and ammonia to condition the water for discharge or reuse in the plant.

Contact us at +1-262-567-7256 or complete our online contact us form for more information.

Written by Sentry Equipment

With proven sampling expertise since 1924, Sentry products and services provide business operations the critical insights to optimize process control and product quality. We deliver true representative sampling and analysis techniques to customers around the globe, empowering them to accurately monitor and measure processes for improved production efficiency, output and safety. Standing behind our commitments, we are determined to tackle any application, anywhere.

Related Posts

Bulk Solid

Maximize Recipe Control with Automatic Sampling

A repeatable, representative sampling of bulk-solid products is essential in today’s production environments. From food production to plastics, automatic samplers are becoming standard practice to provide the needed insights on product quality and safety for profitable production.

Read More

Bulk Solid

How to Maintain Recipe Control with the Sentry SBC Controller

Production of bulk solid materials is dependent on expensive capital equipment, often optimized to produce multiple products on the same line.

Read More

Bulk Solid

Representative Sampling in the Packaging of Nut Butters

Various co-packaging companies provide distributors with multiple types of nut butter products from one processing plant, including items like smooth and chunky peanut butters to almond butters and organic products.

Read More

Designed with You in Mind

Shop our complete line of Low Emission Samplers to find the right fit for your sampling application.