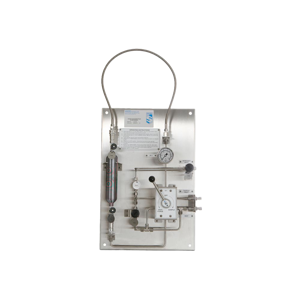

Model MCL Sampler

Part #: 7-04158B

Get Started

Request A QuoteStill Have Questions?

Contact UsDesigned to sample high vapor pressured liquids, the Model MCL Low-E Liquid Sampler uses closed-loop cylinder sampling to safely obtain and transport material.

The Sentry MCL sampler provides representative samples while protecting the safety of operators and the environment. The sampler features a tandem switching valve so multiple functions easily are integrated into one device. All operations are controlled with a simple four-position sample selection valve for ease of operation.

- The MCL sampler comes available with a variety of configurations to ensure that it meets your application needs.

- Additional options include a cylinder relief valve and carbon canisters, ensuring your operators and environment maintain peak safety.

| Wetted Materials | Pressure Range | Temp Range* |

|---|---|---|

|

316 stainless steel, PTFE

O-Rings: FKM or FFKM |

1800 psi (70 bar) | up to 300°F (122°C) |

*higher temp ranges available upon request

Related Resources

Learn more about how the Model MCL Sampler can benefit your application with the following resources.

Need Something Else?

Model C Sampler

Designed to sample gas and high vapor pressure liquids, the Model C Sampler maintains the integrity of your sample while focusing on the safety of your operators and environment.

Model MCG Gas Sampler

Safely sample gas with Sentry’s closed-loop MCG Gas Sampler. By utilizing a sample cylinder, your operator, environment, and sample avoid contamination and danger.