Importance of Degassed Cation Conductivity in Utility Plants

Cation conductivity also responds to less aggressive bicarbonate ions from CO2, which could be considered interference. For this reason, a degassifier is sometimes used to further condition the sample by removing CO2. Called "degassed cation conductivity," it's often conducted at startup when air intrusion is common and can artificially raise the cation conductivity.

Common Degassed Cation Conductivity Methods

Reboiler Degassed Cation Conductivity

Because the pH of a sample following strong cation resin is acidic, most of the CO2 in the sample is dissolved gas. The most common way to remove it is to drive it off with heat using a reboiler. After the sample is passed through the strong acid cation resin, it's heated to near boiling, cooled to 77°F, and then sent to a conductivity meter.

Gas Sparging

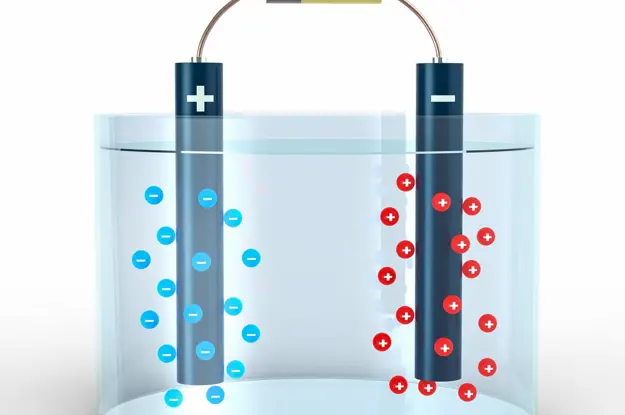

The CO2 in a sample can be removed by sparging it out with nitrogen gas through an empty or packed column. This is often used in larger industrial applications and where an excess of dissolved gas is present.

Gases are dissolved in water in the ratio corresponding to the partial pressure of the gases in contact with it. Since air is mostly nitrogen and oxygen, which will not react with water, only the CO2 fraction contributes to the conductivity of a saturated solution. By sparging with Nitrogen free of CO2, the CO2 is driven off, and the solution conductivity is reduced.

For example, pure water saturated with CO2 can have a conductivity of 1μS, whereas pure water at 77°F has a conductivity of .055 μS. The conductivity increase is due to the conversion of CO2 in water to a weak acid (carbonic acid). In contrast with a gas such as CO2, nitrogen and helium will dissolve in a sample but will not dissociate or react with the water. So, a liquid saturated with inert gas will not show an increase in conductivity.

Written by A.J. Percival

A.J. Percival spent 12 years in the Sentry service group as a technician, training manager, and team manager before transitioning to the Regional Sales Manger role for the Western US in early 2020. He uses his field experience to guide customers to real world solutions for steam and water systems specific to their plants.

Related Posts

Power Generation

Do You Trust Your Process Analytics?

Accurate sampling all depends on regular maintenance. Are you maintaining the critical instruments that your plant relies on?

Read More

Power Generation

Cation Conductivity vs. Specific Conductivity

Conductivity is useful as a general measure of stream water quality. Each stream has a relatively constant range of conductivity. Once a baseline is established, it can be compared with regular conductivity measures.

Read More

Power Generation

Monitoring Cooling Water Systems to Improve Plant Performance

Many plants within the manufacturing industry include processes where the product stream must be heated, cooled, or both to facilitate production. These plants often use heat exchangers or sample coolers with recirculating cooling water systems to do so.

Read More

Protect Your SWAS

Sentry's sampling accessories ensure that you can maintain precise temperatures and/or pressures.