Accurate sampling all depends on regular maintenance. Are you maintaining the critical instruments that your plant relies on?

Since a steam and water analysis system (SWAS) is critical to any power plant, any variation from optimal operation and consistent steam and water sampling can lead to problems that cause added time and expense.

SWAS Maintenance Is Necessary

If you have multiple brands of analyzers installed that aren’t being maintained and calibrated on a regular basis, they aren’t providing accurate data – making it nearly impossible to trust the results.

Neglected SWAS maintenance contributes to ineffective sampling and readings conducted by operators on two 12-hour shifts. This 24-hour vigilance may prevent system malfunction, but the human element could introduce inaccuracies and, ultimately, bigger problems for the plant on the whole.

Something as simple as a clogged filter can sabotage your process analytics. Many filters, like in your coffeemaker, have a disposable element to be changed. If the filter does not have a disposable element, it will have one that must be regularly cleaned. Regardless of filter media, proper maintenance is required to avoid plugging, which chokes off flow to the downstream conditioning and analytics system.

How To Win Back Trust

Accurate sampling all depends on regular maintenance. Are you maintaining the critical instruments that your plant relies on?

The critical questions to ask:

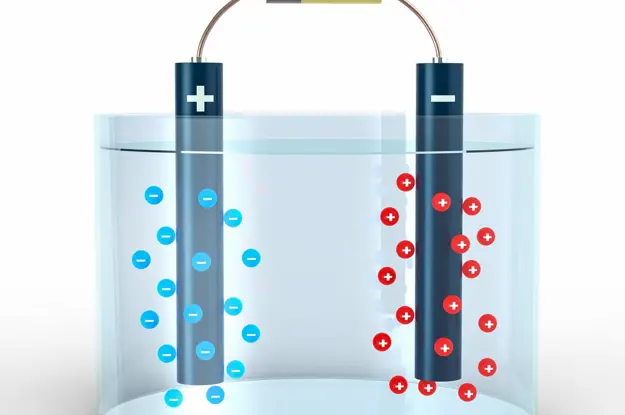

- What type of chemistry are you running to control pH?

- Are you relying on sample panel instrumentation to control chemical feed pumps?

- What parameters are controlling the feed pumps with- pH, specific conductivity?

- What type of heat rejection does your plant use?

- Do you have a good sodium analyzer on the condensate to go along with cation conductivity?

Answering these questions to develop proactive SWAS maintenance plan will go a long way in controlling costs and ensuring accurate process analytics that you can trust. Partnering with a trusted factory-trained and authorized service team, like the one found behind Sentry ProShield Guardian service agreements, is another option to ensure your analytics are always accurate.

Contact us today so you can trust your process analytics again.

Written by Sentry Equipment

With proven sampling expertise since 1924, Sentry products and services provide business operations the critical insights to optimize process control and product quality. We deliver true representative sampling and analysis techniques to customers around the globe, empowering them to accurately monitor and measure processes for improved production efficiency, output and safety. Standing behind our commitments, we are determined to tackle any application, anywhere.

Related Posts

Power Generation

Cation Conductivity vs. Specific Conductivity

Conductivity is useful as a general measure of stream water quality. Each stream has a relatively constant range of conductivity. Once a baseline is established, it can be compared with regular conductivity measures.

Read More

Power Generation

Monitoring Cooling Water Systems to Improve Plant Performance

Many plants within the manufacturing industry include processes where the product stream must be heated, cooled, or both to facilitate production. These plants often use heat exchangers or sample coolers with recirculating cooling water systems to do so.

Read More

Power Generation

Prepare Your Equipment for the Summer Heat with a Two-Stage Cooling Configuration

Avoiding extreme summer weather and even regular summer weather is not avoidable, and these conditions can cause havoc on steam and water analysis systems (SWAS) without adequate preparation.

Read More