CASE STUDY: How to Increase the Efficiency of your Facility with Used Equipment

In 2023, the U.S. consumed 50 million metric tons of iron and steel increasing the consumption by 2 million metric tons from 2022, and the number continues to balance in between 45 and 65 million metric tons since 2006. This number has made iron and steel the most recycled metal in 2023, but, in 2024, the numbers are estimated to decrease. With the help of facilities selling their equipment back to the original manufacturer, we can predict the number of metal going to scrap to be less in the coming years.

Options for Disposing Equipment:

When a company requires the disposal of equipment, many may send their equipment to scrap, however, another opportunity for disposal is selling the machine back to the original manufacturer. If the original manufacturer accepts used equipment, this opens the opportunity for retrofitting the equipment for use in another facility.

SmartSkim, by Sentry Equipment, has experienced the opportunity to help a company by creating a solution for a client that includes a used piece of equipment and fit it to their needs.

Install and Retrofit:

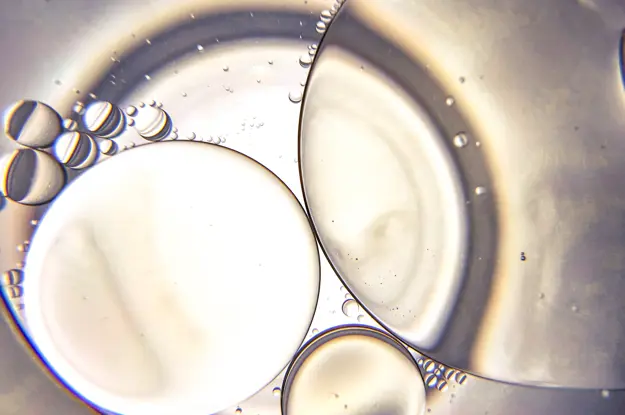

A machine shop in St. Louis has seen exponential growth and needed to upgrade their facility with new and larger contamination removal tanks to keep up with their operations. They reached out to Bill Gimbel, Sentry Equipment's Regional Sales Manager for SmartSkim, and he was able to solve their wants quickly by discovering their needs and ensuring the used equipment was customized to fit their facility. With the knowledge and guidance from Bill, the St. Louis machine shop added a SmartSkim CL1200 Recycling System to their line of equipment. The CL1200 quickly promotes the capture and separation of contaminated floating oils and suspended solids from valuable machining coolants maximizing the return on investment.

Not only can you help decrease the amount of unusable metals that are consumed each year in scrap, but you can also impact another company as they continue to grow by selling your used equipment.

If you are looking to upgrade or add a SmartSkim, by Sentry Equipment product to your facility, contact us at +1-262-567-7256, or complete our online contact form.

Written by Sentry Equipment

With proven sampling expertise since 1924, Sentry products and services provide business operations the critical insights to optimize process control and product quality. We deliver true representative sampling and analysis techniques to customers around the globe, empowering them to accurately monitor and measure processes for improved production efficiency, output and safety. Standing behind our commitments, we are determined to tackle any application, anywhere.

Related Posts

Oil Separation/Coolant Recycling

How to Increase the Efficiency and Output of Your Evaporator

As EPA (Environmental Protection Agency) expands regulations and enforcement on the discharge and disposal of industrial fluids from metalworking and metal-finished plants, we can see more equipment being purchased to treat and or solve tSmartSkim Recycling & Filtrationhe problem of waste.

Read More

Oil Separation/Coolant Recycling

Reduce Operation Costs with a Coolant Recycling System

Manufacturing processes are inundated with lubricants and other industrial fluids. Managing these fluids is critical to protecting equipment and ensuring worker safety.

Read More

Maximize Manufacturing Processes

Sentry's SmartSkim product line can help maximize your manufacturing processes with coolant recycling and oil separation technology.