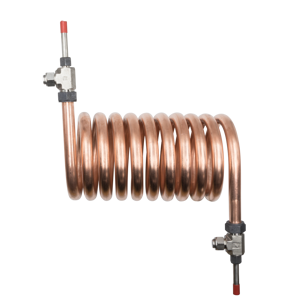

Spiral Tube Heat Exchanger

Part #: TBD

Get Started

Request A QuoteStill Have Questions?

Contact UsMaintain heat transfer efficiency and maximize your plant footprint with our compact, lightweight Spiral Tube Heat Exchanger.

- Meet robust sample conditions – The spiral heat exchanger can withstand pressures up to 5000 psi (345 bar) and temperatures up to 1000°F (540°C).

- Enhances heat transfer on both sides with a true counterflow arrangement.

- Doesn’t require tube supports or pass dividers to function.

| Shell Design | Tube Design | Shell Material | Tube Material |

|---|---|---|---|

| 150 psig at 400°F (10.3 barg at 204°C) |

up to 5000 psig at 1000°F (up to 345 barg at 540°C) |

carbon steel and stainless steel |

stainless steel, Hastelloy, Alloy 625, |

Related Resources

Learn more about how the Spiral Heat Exchanger can benefit your application with the following resources.

Need Something Else?

Review some other related products that could help your current application.

DTC Tube-in-Tube Heat Exchanger

The DTC Tube-in-Tube Heat Exchanger helps manage low flow rate and high temperature and/or high-pressure fluids through its spiral wound, counter flow design.

TCU Sample Chiller

Have confidence in your sample temperatures with Sentry's Temperature Control Unit. Used in conjunction with a secondary cooling system, these units can handle a wide variety of heat loads all while cooling water within 1 F (0.5 C) of target.