Model G Cross-cut Sampler

Get Started

Request A QuoteStill Have Questions?

Contact UsObtain representation of your entire vertical or inclined product stream with the Sentry Model G Cross-Cut Sampler.

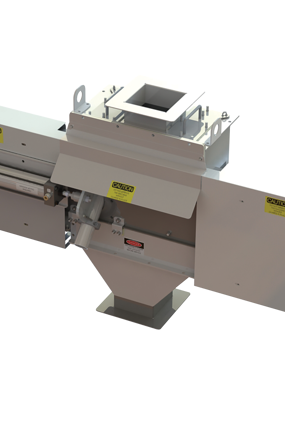

By taking a cross section of grain, granules, or flakes as it travels down a chute, the sampler can get a representative sample of your process without affecting the product characteristics.

- This bulk solids sampler has a variety of options to suit specific applications – wear liners, QPQ hardening, pre-plumbed filter-regulator, and more.

- Sampler can be pneumatically, electrically, or hydraulically driven.

- Available in square or round gravity chutes and two- or three-inch (51 or 76 mm) discharge tubes to accommodate different particle sizes.

- Meets USDA, CRN, FGIS, and NOPA compliance standards

- Seal kits and sample containers available to meet your repair and sampling needs

Particle Size

- The FGIS certified Cross-Cut G sampler has a recommended particle size of 10 µm to .25 in (6 mm).

- Contact us if you require larger particle sizes.

Process Locations

- The Model G Sampler's recommended sampling location is in vertical or inclined gravity spouts.

- The sampler dimensions are dependent on process customization.

Related Resources

Learn more about how the Model G Sampler can benefit your application with the following resources.

Need Something Else?

Review some other related products that could help your current application.

Model SA Sampler

Obtain representation of your entire vertical product stream with the Sentry Model SA Sampler.

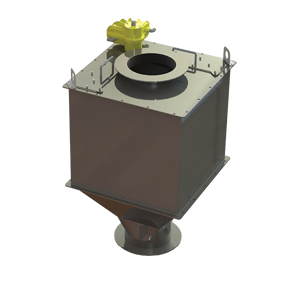

SBC Controller

Automate your bulk solid sampling with Sentry's SBC Controller. Utilizing a few simple connections, the controller ensures operators can automate a single or continuous sample with any Sentry ISOLOK or bulk solid sampler.