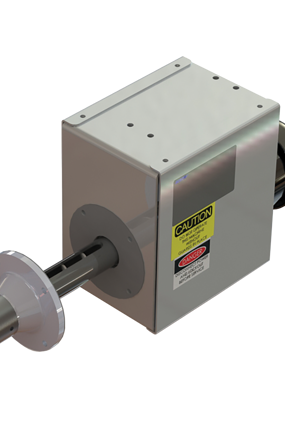

Model D2 Bulk Solids Sampler

Get Started

Request A QuoteStill Have Questions?

Contact UsThe Sentry D2 strip sampler captures a sample across the width of your process streams to ensure your samples are representative. Used in situations where product segregation exists, you can rest assured that characteristics, such as particle size, are not affected by the sampler.

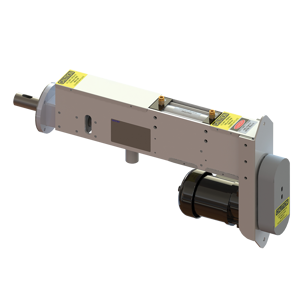

The Sentry D2 sampler collects a sample by rotating an outer sample tube via an actuator, exposing an aperture to the product flow. Simultaneously, a motor-driven auger conveys the product to a discharge point. Each sample size is controlled and can be changed with a sampler controller, allowing for maximum control over your processes.

- Close tolerance between the auger and tube assures self-cleaning to help prevent cross-contamination.

- This bulk solids sampler has a variety of options to suit specific applications – release coating, QPQ hardening, pre-plumbed filter, and more.

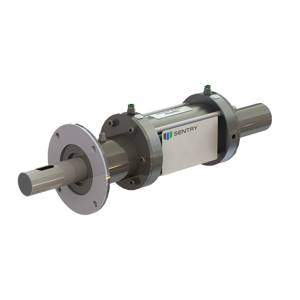

- The Model D2 requires minimal head installation height and is available in same-side discharge (SSD) version for installations with space constraints.

- Seal kits and sample containers available to meet your repair and sampling needs

Particle Size

- The recommended particle size for the D2 sampler is 10 µm to .25 in (6 mm).

- Same side discharge option available for when clearance is limited to one side of the process line.

Process Locations

- The bulk solid sampler recommended sampling location is in gravity chutes and hoppers.

- The sampler dimensions are dependent on process customization and insertion lengths starting at 6 in (152 mm).

FAQ Sampling Questions

Sentry's bulk solid and ISOLOK sampler maintenance schedules depend on the application. However, it is recommended to clean your equipment every 6 months and review cycle counts to determine the average change time of seals. You should also document every failure for a more robust maintenance schedule.

Related Resources

Learn more about how the Model D2 Sampler can benefit your application with the following resources.

Need Something Else?

Review some other related products that could help your current application.