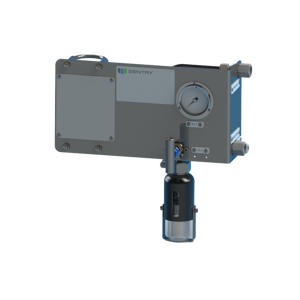

Model MIL Liquid Sampler

Part #: 7-03844F

Get Started

Request A QuoteStill Have Questions?

Contact UsThe Model MIL Liquid Sampler uses a close-coupled ball valve to extract samples from in-line petrochemical, refining, and nuclear process piping. This liquid sampler creates a low dead volume in the sample flow area, ensuring representative sampling and a clear sample stream.

In addition to sample integrity, the low-e liquid sampler ensures operator safety through a side-discharge dual needle assembly, adjustable throttle stop, and spring-loaded throttling valve, ensuring operators can close the line quickly without accidental spillage or contamination.

- The MIL sampler comes available with a variety of configurations to ensure that it meets your application needs.

- Extra safety is available with an optional enclosure.

| Wetted Materials | Pressure Range | Temp Range |

|---|---|---|

|

body: 316 stainless steel

O-rings: FKM or FFKM ball valve seats: PTFE-Teflon or PEEK* |

2200 psi (152 bar) | up to 450°F (232°C) |

*nuclear only

Related Resources

Learn more about how the Model MIL Sampler can benefit your application with the following resources.

Need Something Else?

Review some other related products that could help your current application.