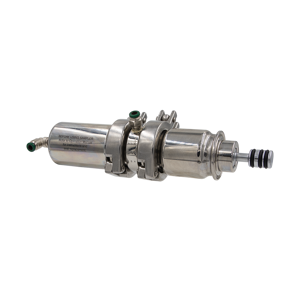

MSD Sampler

Get Started

Request A QuoteNot What You're Looking For?

Contact UsDesigned for high-viscosity applications such as toothpaste, peanut butter, and concentrates, the ISOLOK MSD high-pressure sampler ensures that your samples are representative of your entire food and beverage process.

This automatic sampler's contracting annulus and sanitary construction ensure that you are meeting the demands of your processes and isolating the sample from human bias. This sampler is best suited for lines with pressures greater than 30 Psi.

- This sampler captures 14 cc per cycle

- A variety of customizations are available from port closures, line adapters, different containers, and more.

- The sampler's tri-clamp mounting design allows for easy installation, maintenance, and versatility with a variety of process lines.

Temperature

- ISOLOK MSD ambient operating temperature -5˚ to 131˚F (-20˚ to 55˚C), depending on the seal material

- The sample material temperature can be -40˚ to 500˚F (-40˚ to 260˚C), depending on seal material and duty cycle.

Pressure

- The MSD sampler can handle up to 150 PSI (10.3 bar) process pressure.

- Contact our team if higher pressures are needed.

Related Resources

Learn more about how the MSD Sampler can benefit your application with the following resources.

Need Something Else?

Review some other related products that could help your current application.