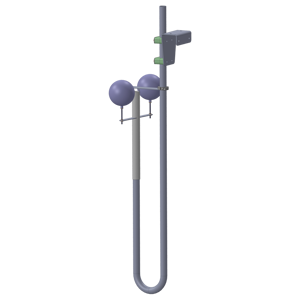

V Series Oil Separator

Get Started

Request A QuoteStill Have Questions?

Contact Us

Minimize floor space and maximize your industrial processes with the Sentry V Series Vertical Oil Separator. This coalescing separator is designed to simply remove free-floating and mechanically dispersed tramp oils from wash tanks and other manufacturing process fluids.

By using a gravity flow process, the V Series oil separator reduces tramp oils to less than 1% in a single pass while minimizing clogging concerns. Applications include water soluble, semi-synthetic & synthetic coolants from machining and grinding, alkaline washwaters, stamping fluids, wastewater pre-treatment, aqueous quench pits, die casting mold release fluids, and any application where separation of two immiscible fluids is required.

Inside the SmartSkim V Series Separator, there are no plastic coalescer media, filters, or consumables of any kind. Our proprietary open channel system separates and removes floating oils and solids by gravity only. This makes maintenance fast and easy.

Inside the SmartSkim V Series Separator, there are no plastic coalescer media, filters, or consumables of any kind. Our proprietary open channel system separates and removes floating oils and solids by gravity only. This makes maintenance fast and easy.

- Reduces new fluid purchase costs by up to 75% by extending the life of those fluids

- The V Series Oil Separator reduces waste volumes by up 50-90%.

- Minimizes the cost of wash water detergent, heating, and disposal costs.

- Ensures safety by reducing misting and smoke, environmental waste disposal, and bacteria levels.

| Process Pressure | Flow Rate | Input Power |

|---|---|---|

| 30 PSI (2.07 bar) |

up to 3 GPM (3-7 scfm)

|

60-120 PSI 6cfm |

Related Resources

Learn more about how the CrossFlow Oil Separator can benefit your application with the following resources.

Browse All Resources

Explore more information on SmartSkim products and services in our Resource Library.

Need Something Else?

Review some other related products that could help your current application.