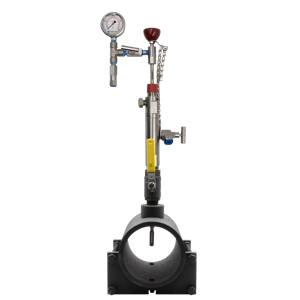

Saf-T-Vise Insertion Tools

Part #: 6-06202

Get Started

Request A QuoteStill Have Questions?

Contact UsSentry Saf-T-Vise insertion tools are used to insert and remove corrosion coupon holders, injection & sample quills, or chemical injection nozzles & atomizers—without shutting down the system.

Weighing 5x less than other products, Saf-T-Vise insertion tools are light enough for a single operator, yet these tools are strong enough to perform as intended. These corrosion insertion tools are designed to make insertion and removal of corrosion monitoring devices safe, easy and fast in high-pressure applications.

- The insertion tool is used only during the installation or removal processes and can be removed once that operation has been completed.

- Their removability allows a single device to service multiple installations, reducing the operating cost of monitoring the process for corrosion.

- The operator can work from a stable and secure position beside the tool, which can be inserted from any location.

| Model | Operation | Pressure Rating (MOP) | Travel Length |

| STV-T1 | Handwheel | 5000 PSI at 100°F (345 bar at 38°C) |

24 to 36 in (61 to 91 cm) |

| STV-T4 | Side Crank | 10000 PSI at 100°F (689 bar at 38°F) |

8 in (20 cm) |

| STV-T5 | Side Crank | ≤ 30 in: 5000 PSI at 100°F (345 bar at 38°F) > 30 in: 3000 PSI at 100°F (206 bar at 38°F) |

14 to 42 in (36 to 107 cm) |

Related Resources

Learn more about how the Saf-T-Vise Insertion Tools can benefit your application with the following resources.

Need Something Else?

Review some other related products that could help your current application.