Saf-T-Vise Chemical Injection Atomizer

Get Started

Request A QuoteStill Have Questions?

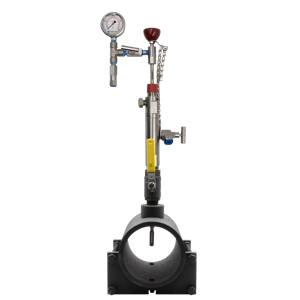

Contact UsSentry Saf-T-Vise chemical injection atomizers contain a patented safety feature to deliver a customized, secure user-experience.

Our atomizers features an easy-to-use collet that locks within the process stream in both low and extremely high-pressure conditions for safe and even chemical distribution. Each atmoizer is available with seals - Teflon seals for natural gas applications and Graphoil seals for liquid applications. In addition, a variety of atomizer configurations are available to optimize the delivery of the required chemicals to prevent or reduce corrosion within a high-pressure pipeline.

- To avoid corrosion and equipment damage and enable accurate monitoring, Saf-T-Vise comes with a materials certification and test summary to confirm the product’s materials.

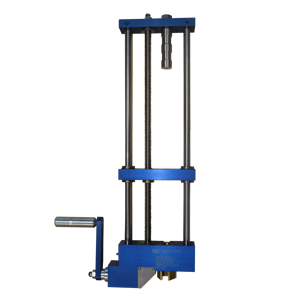

- Saf-T-Vise atomizers protect operator safety by offering mechanical insertion capability that can mount in any orientation at various extension lengths up to 20 feet.

- The components are tested at safety pressure 1.5x the operating pressure to assure compliance with PHMSA regulations and NACE standards.

- All STV products are designed to be installed or removed under live field conditions.

Materials

- Each of Sentry's chemical injection atomizers are made with 316/316L stainless steel.

- If you need other alloys, please contact our team for more information.

Atomization Rates

- Atomization rates start at 5 Gallons per day and go up from there.

Pressure

- The STV atomizers can also handle a max pressure of 5000 PSI at 100˚ F (517 bar at 38˚ C), depending on the model.

Insertion Depth

- Depending on the model, each chemical atomizer can manage an overall length of up to 240 in (6.1 m) inside the process.

- A portable insertion tool may be required depending on the atomizer model selected.

Related Resources

Learn more about how the Saf-T-Vise Chemical Atomizers can benefit your application with the following resources.

Need Something Else?

Review some other related products that could help your current application.