Corrosion Protection

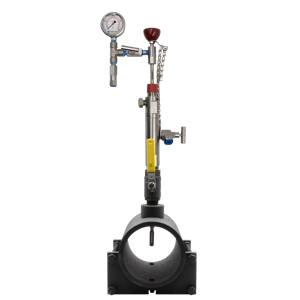

Saf-T-Vise Chemical Injection Atomizer

Mitigate corrosion concerns with a chemical injection atomizer.

Saf-T-Vise Corrosion Coupon Holders

Expose pipeline metal to your process to discover corrosion rates.

DPA Drip Pot Assemblies

Sentry DPA is easy-to-use for collecting samples within pressurized systems

Saf-T-Vise Corrosion Monitoring Probes

Handle small materials and expose them to the process for monitoring

Saf-T-Vise Injection & Sample Quills

Sentry Saf-T-Vise quills monitor corrosion and enable real-time decisions.

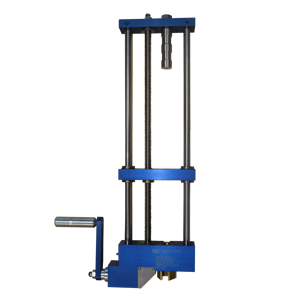

Saf-T-Vise Insertion Tools

Corrosion coupon holders & sample quills without shutting down the system

Protection from Corrosive Damage

Safely treat and protect your pipelines with Sentry's complete portfolio of corrosion protection equipment. From monitoring to corrosion mitigation, Sentry Equipment has the expertise to meet your application requirements.

With the Sentry Saf-T-Vise line, operators can accurately monitor potential corrosion and rectify it when corrosion arises. From corrosion coupon holders to insertable chemical injection atomizers, our patented collet locking design ensures operator safety, optimal function, and ease-of use.

Protect yourself from corrosion in both low and extreme high-pressure conditions with our product suite below.

Reliable Corrosion Sampling and Corrosion Monitoring Solutions

Corrosion monitoring is crucial across a wide range of manufacturing and industrial processes, where metal degradation can compromise safety, performance, and regulatory compliance. From refining and petrochemical facilities to water treatment plants and food production lines, effective corrosion sampling helps detect early signs of wear in piping systems, vessels, and other critical components.

Whether you're monitoring chemical injection points, process media, or high-pressure systems, robust corrosion sampling ensures accurate data for preventative maintenance. As part of a comprehensive integrity program, pipeline corrosion monitoring remains especially crucial for identifying risks in flowlines and maintaining uninterrupted operations.