Liquid & Slurry

Liquid & Slurry Solutions

Ensure your product and bottom line remain safe by implementing reliable and accurate sampling equipment. This regular sampling at every stage of the production process is critical to your product and efficiency. Learn more about how Sentry's high viscosity samplers can protect your products and minimize the impact to your bottom line.

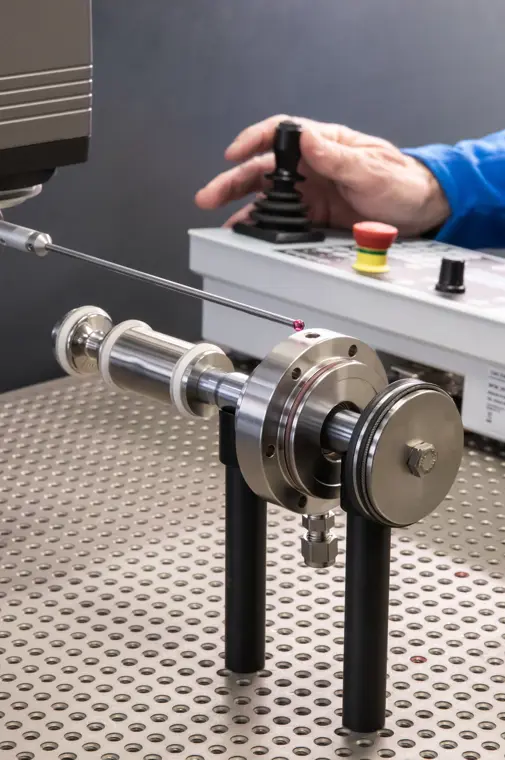

ISOLOK Samplers

Ensure your products and bottom line are safe with representative sampling that includes reliable and accurate analysis results.

Learn More

Corrosion Monitoring

Safely treat and protect your pipelines with Sentry's complete portfolio of corrosion protection equipment.

Learn More

Startup & Training

Empower your employees to become sampling experts with customized training and startup assistance.

Learn More

Sampling Parts & Accessories

Add a layer of extra protection from corrosion, inconsistent temps, and impurities with Sentry's sampling parts and accessories.

Learn MoreAchieve Safe, Simple, and Accurate Sampling

Reliable and accurate liquid and slurry sampling solutions keep your system running smoothly. Sentry ensures your samples are at a flow rate appropriate for your needs, has no leaks, retains the correct temperature, and runs safely and accurately to help achieve successful results.

We understand the need to sample at every stage of the production process, ensuring your product and bottom line remain safe so, we offer samplers that can handle higher viscosity that any other competitors. Our customer's goal to capture liquid and slurry samples simply, safely, and accurately is our top priority.

Trust the Pros That Know

Critical cycle chemistry analytics and conditioning equipment can become obsolete ahead of plan, resulting in the need for safe, efficient technology updates.

Sentry's ProShield technicians go beyond one-size-fits-all to provide installation, product support, and application engineering to custom design updated solutions for your existing steam and water analysis system. Each installation and retrofit starts with a complete review of the system (SysRep) and takes into account a holistic, iterative focus to minimize impacts to your processes and equipment.

By focusing on reliability and brand inclusivity, you are able to get the full range of expertise from our trusted technicians.

Looking for More Information?

Learn more about the impacts of preventative maintenance and sampling management with these related resources.

What is Representative Sampling?

Operators can produce reliable and accurate analysis results that meet federal requirements through representative sampling. Learn how you can implement this at your plant through our beginner’s guide.

Download the eBook

Food and Beverage Sampling Brochure

In the world of food testing, the analytical techniques to measure the threats are precise, often down to the sub-parts-per-trillion level. Learn how sampling can help you manage that precision.

Download Now

Automatic Sampler Brochure

A food safety sampling and analysis program provides controlled, real-time data and is aligned with regulatory requirements. Learn how automatic sampling can help manage these operational needs.

Download Now

Maintain Your Sampling Equipment

The ISOLOK SAA automatic point sampler provides representative samples of liquids and slurries. This is ideal for a variety of industries, learn how to maximize yours within this How-To video.

View NowRecommended Product Lines

Get started finding the right equipment for your application with these recommended products by Sentry Equipment.

Need More Insight?

Explore our blog, the Shield, for more Liquid and Slurry application information.