Bulk Solids

Solutions to Fit Your Needs

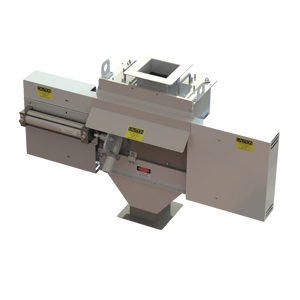

Every bulk solids production environment is different. Homogenous operations, such as flour milling, and heterogenous operations, such as pet food and co packaging, need to meet different analytical and compliance requirements. Sentry creates solutions to meet the needs of every bulk solids application and support them throughout their lifecycle.

Maximum Production with Minimal Interruption

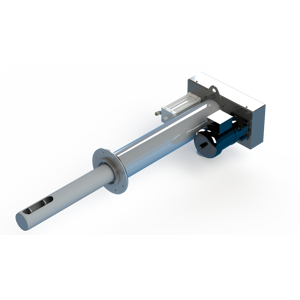

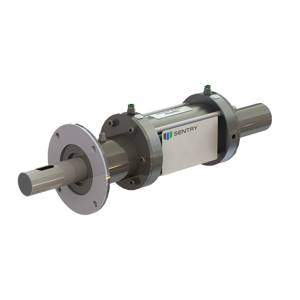

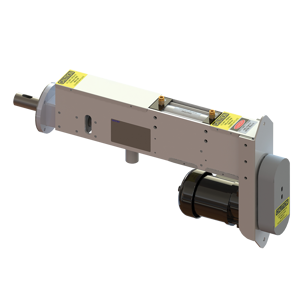

Manufactured precisely to ensure maximum stability, accuracy, and durability, Sentry's solutions for sampling of bulk materials allow operators to accurately test everything from the finest powders to the largest granules. We understand that maximizing production and minimizing costs are the utmost importance to your operations. That is why our team focuses on keeping you up and running without infringing on current process lines.

Utilizing a representative sampling methodology, each bulk solid solution ensures that you are meeting compliance and accurately testing across the entire batch. This way each customer can trust that they are maintaining product quality, minimizing contamination, and maximizing production.

Looking for More Information?

Learn more about the impacts of preventative maintenance and sampling management with these related resources.

What is Representative Sampling?

Operators can produce reliable and accurate analysis results that meet federal requirements through representative sampling. Learn how you can implement this at your plant through our beginner’s guide.

Download the eBook

Automatic Sampler Brochure

A food safety sampling and analysis program provides controlled, real-time data and is aligned with regulatory requirements. Learn how automatic sampling can help manage these operational needs.

Download Now

Food and Beverage Sampling Brochure

In the world of food testing, the analytical techniques to measure the threats are precise, often down to the sub-parts-per-trillion level. Learn how sampling can help you manage that precision.

Download Now

The Future of Bulk Solid Sampling

Bulk Solid Producers rely on sampling to ensure their product quality and maximize production. Watch our experts discuss the future of bulk solids sampling.

View NowRelated Products

Get started finding the right equipment for your application with these recommended products by Sentry Equipment.