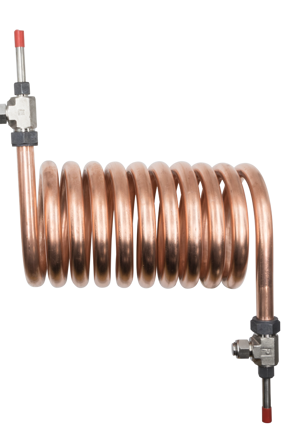

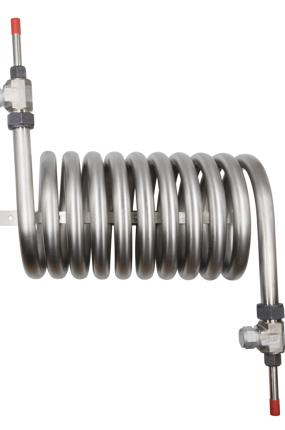

DTC Tube-in-Tube Heat Exchanger

Part #: 7-06469A

Get Started

Request A QuoteStill Have Questions?

Contact UsThe DTC Tube-in-Tube Heat Exchanger helps manage low flow rate and high temperature and/or high-pressure fluids through its spiral wound, counter flow design.

Made with a variety of applications in mind, the heat exchanger’s base tube-in-tube design allows for reliability, efficiency, and minimal downtime through simplistic design and minimal operator intervention.

- The DTC Heat Exchanger has a constant fluid velocity, while ensuring no dead spots or crevices.

- Making it easier to service, this heat exchanger provides a completely drainable design.

- The product can be made with a variety of materials such as:

- Stainless Steel

- Copper

- Nickel Alloys

- Titanium

- Zirconium

- The Sentry Tube-in-Tube Heat Exchanger is excellent for multi-phase fluids and slurries due to its resistance to thermal and hydraulic shock.

- Meets Sanitary 3A, ASME B31.1, and ASME B31.3 compliance standards

| Models | Inner Tube Design | Outer Tube Design | Inner Tube Material | Outer Tube Material |

|---|---|---|---|---|

| DTC-CUA/CUA-4 | 2000 psi at 300°F (137 bar at 148°C) |

700 psi at 300°F (48 bar at 148°C) |

1/4 in OD copper | 1/2 in OD copper |

| DTC-SSA/CUA-4 | 4900 psi at 1000°F (337 bar at 537°C) |

700 psi at 300°F (48 bar at 148°C) |

1/4 in OD 316SS | 1/2 in OD copper |

| DTC-IN1/CUA-4 | 5450 psi at 1100°F (375 bar at 593°C) |

700 psi at 300°F (48 bar at 148°C) |

1/4 in OD Alloy 625 | 1/2 in OD copper |

| DTC-SSA/SSB-4 | 4900 psi at 1000°F (337 bar at 537°C) |

2300 psi at 1000°F (158 bar at 537°C) |

1/4 in OD 316SS | 1/2 in OD 316SS |

| DTC-IN1/SSB-4 | 5450 psi at 1100°F (375 bar at 593°C) |

2300 psi at 1000°F (158 bar at 537°C) |

1/4 in OD Alloy 625 | 1/2 in OD 316SS |

| DTC-CUA/CUB-6 | 1250 psi at 300°F (86 bar at 148°C) |

700 psi at 300°F (48 bar at 148°C) |

3/8 in OD copper | 3/4 in OD copper |

| DTC-SSC/CUB-6 | 5100 psi at 1000°F (351 bar at 537°C) |

700 psi at 300°F (48 bar at 148°C) |

3/8 in OD 316SS | 3/4 in OD copper |

| DTC-IN1/CUB-6 | 3800 psi at 1100°F (262 bar at 593°C) |

700 psi at 300°F (48 bar at 148°C) |

3/8 in OD Alloy 625 | 3/4 in OD copper |

| DTC-SSC/SSC-6 | 5100 psi at 1000°F (351 bar at 537°C) |

2300 psi at 1000°F (158 bar at 537°C) |

3/8 in OD 316SS | 3/4 in OD 316SS |

| DTC-IN1/SSC-6 | 3800 psi at 1100°F (262 bar at 593°C) |

2300 psi at 1000°F (158 bar at 537°C) |

3/8 in OD Alloy 625 | 3/4 in OD 316SS |

| DTC-CUB/CUC-8 | 1250 psi at 300°F (86 bar at 148°C) |

700 psi at 300°F (48 bar at 148°C) |

1/2 in OD copper | 1 in OD copper |

| DTC-SSB/CUC-8 | 2400 psi at 1000°F (165 bar at 537°C) |

700 psi at 300°F (48 bar at 148°C) |

1/2 in OD 316 SS | 1 in OD copper |

| DTC-IN7/CUC-8 | 4000 psi at 900°F (276 bar at 482°C) |

700 psi at 300°F (48 bar at 148°C) |

1/2 in OD Alloy 625 | 1 in OD copper |

| DTC-SSB/SSD-8 | 2400 psi at 1000°F (165 bar at 537°C) |

2300 psi at 1000°F (158 bar at 537°C) |

1/2 in OD 316 SS | 1 in OD 316 SS |

| DTC-IN7/SSD-8 | 4000 psi at 900°F (276 bar at 482°C) |

2300 psi at 1000°F (158 bar at 537°C) |

1/2 in OD Alloy 625 | 1 in OD 316 SS |

| DTC-SSG/SSC-6 | 150 psi at 450°F (10 bar at 232°C) |

1100 psi at 200°F (76 bar at 93°C) |

3/8 in OD 316 SS, electropolished |

3/4 in OD 316 SS |

| DTC-SSG/SSD-8 | 150 psi at 350°F (10 bar at 177°C) |

1100 psi at 200°F (76 bar at 93°C) |

1/2 in OD 316 SS, electropolished |

1 in OD 316 SS |

Related Resources

Learn more about how the Tube-in-Tube Heat Exchanger can benefit your application with the following resources.

Need Something Else?

Review some other related products that could help your current application.

Spiral Tube Heat Exchanger

Maintain heat transfer efficiency and maximize your plant footprint with our compact, lightweight Spiral Tube Heat Exchanger.

TCU Sample Chiller

Have confidence in your sample temperatures with Sentry's Temperature Control Unit. Used in conjunction with a secondary cooling system, these units can handle a wide variety of heat loads all while cooling water within 1 F (0.5 C) of target.