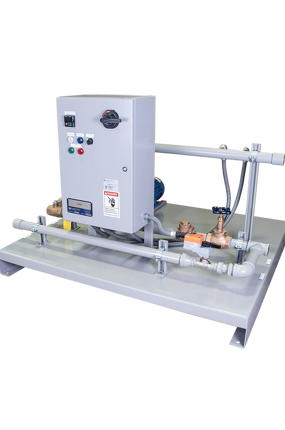

CWMS Cooling Water Mixing Skid

Part #: 7-02105

Get Started

Request A QuoteStill Have Questions?

Contact Us

Manage insufficient water pressure or seasonal temperature variations efficiently with Sentry's CWMS Cooling Water Mixing Skid.

The skid works by recirculating water to control a consistent temperature and pressure using existing chilled water sources vs. a mechanical chiller. A digital control adds a layer of confidence by allowing operators to create a set point while the water skid takes care of the rest.

- The CWMS Water Mixing Skid controls temperatures within ± 1°F (0.5°C) with an electronic controller and modulating ball valve.

- Optional dual pumps and oversized makeup and discharge lines/valves are available upon request.

| Model | Recirculating Flow | Pump Horsepower |

|---|---|---|

| CWMS-35 | 35 GPM | 2 HP |

| CWMS-80 | 80 GPM | 3 HP |

| CWMS-140 | 140 GPM | 5 HP |

Related Resources

Learn more about how the CWMS Cooling Water Mixing Skid can benefit your application with the following resources.

Need Something Else?

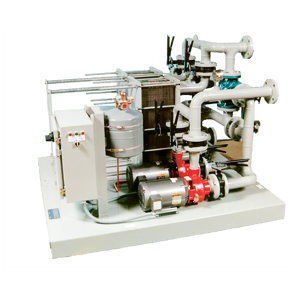

CWIS Cooling Water Isolation Skid

Sentry's CWIS Cooling Water Isolation Skid helps control the negative consequences associated with water and temperature inconsistency.

TCU Sample Chiller

Have confidence in your sample temperatures with Sentry's Temperature Control Unit. Used in conjunction with a secondary cooling system, these units can handle a wide variety of heat loads all while cooling water within 1 F (0.5 C) of target.